Our Project

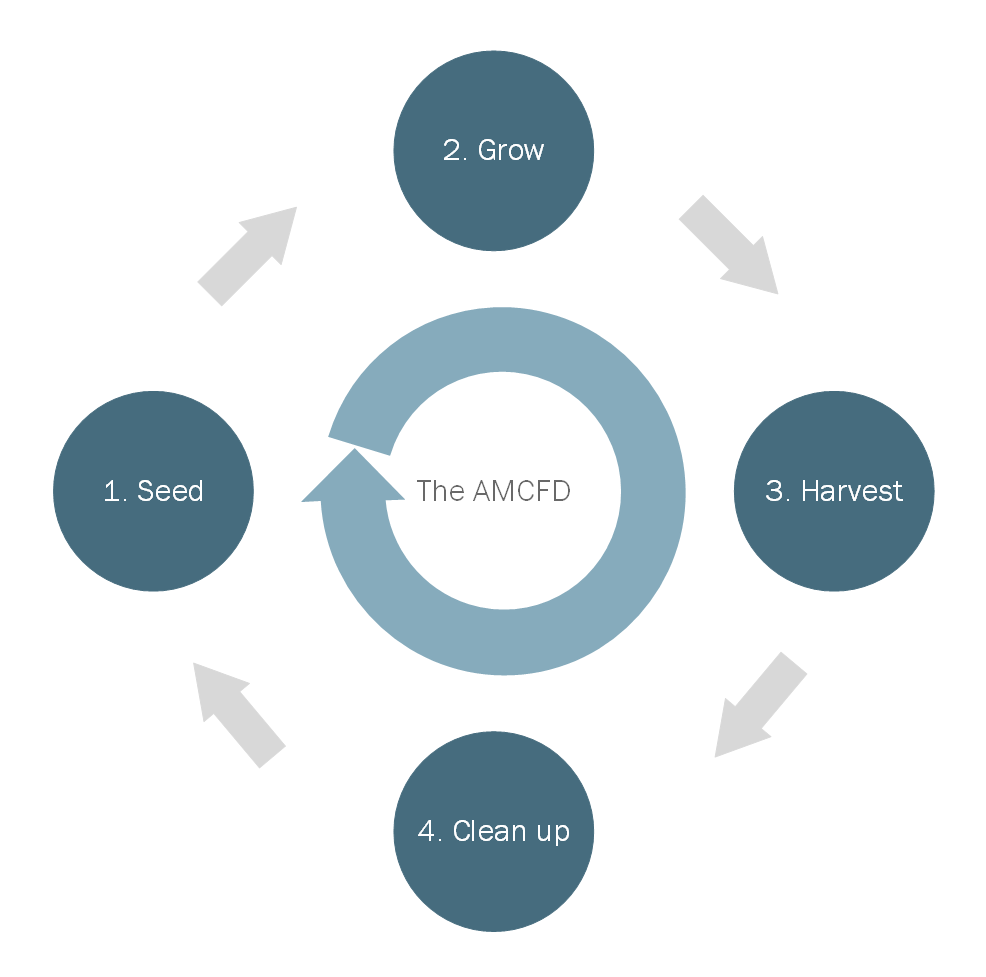

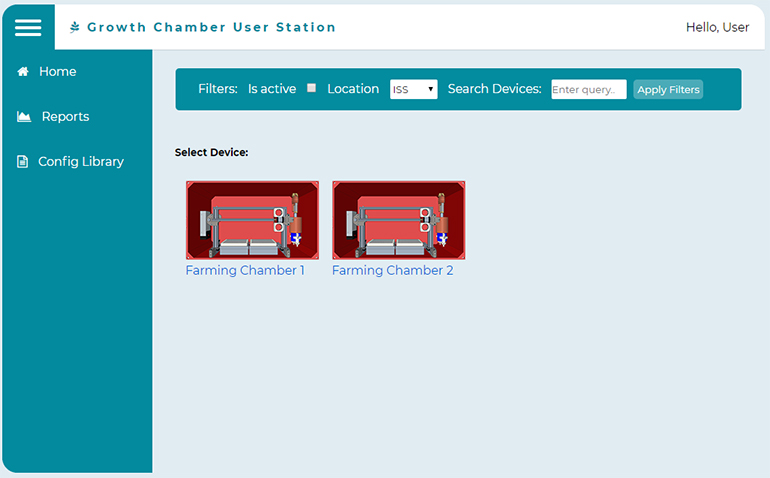

With NASA gearing up for the Artemis program and space exploration expanding rapidly to accommodate life beyond Earth, there exists a need to grow food autonomously that can support humans reliably, without compromising valuable time, or energy, from other missions in space. Therefore, students across multiple disciplines joined forces to build an Autonomous Multiple Cycle Farming System (AMCF) that grows plants autonomously through robotic functions with limited human interaction for multiple cycles.

How it works